HALS is a

lens sheet for 3D printing

HALS is a

lens sheet for 3D printing

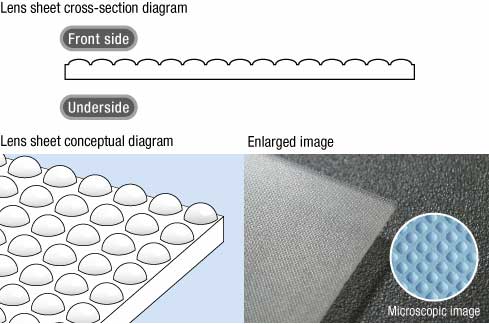

HALS is a micro lens sheet, with lens processing carried out on the surface

of its base material (such as PP or PET).

Micro lenses are formed on the front side, creating a surface asperity at

the micron level. The underside is a flat, smooth surface.

HALS Lens Sheet

HALS Printing

HALS Printing

Please print HALS Lens Sheet by using UV Offset Printing Machinery.

There are two(2) kinds of printing methods for HALS printing as follows.

Underside HALS printing only |

Both side HALS printing |

|

The image for color photo |

It is possible to combine with HALS back pattern

(In case of process color) |

Prepared CMYK image (equivalent to general printing) |

The image for 3D back pattern |

It is possible to combine with color photo image (In case of process color) |

Special image for 3D back pattern |

Required printing units |

7 units ( In case of using special color for 3D back pattern ) |

5 units |

One pass printing |

Possible |

Not possible in general |

Difficulty for platemaking |

Slightly complicated |

Easy |

Countermeasure of Moire effect for color Image |

High resolution halftone is necessary (Ex. : around 300 lpi or stochastic) |

Not necessary |

Superiority of printing cost |

High |

Normal |

Yield rate for production |

Good, one (1) passing. |

Spares for 2 times passing are required. |

HALS Printing Structural Diagram

Creating HALS

design data

Creating HALS

design data

When you make a design for HALS, You can use the same DTP software, which is used to produce general printed matter. Concerning the data for the graphics plate (4 colors : CMYK ) which printed on the micro-lens side is produced in the same way for normal printing. Regarding HALS pattern plate which printed on the underside of HALS lens sheet is designed by using adobe Illustrator after choosing desired pattern form the “HALS Pattern Data” provided by GRAPAC. Please prepare white plate which you use as an opaque background for the graphics and HALS pattern, and then all required data production is completed.

DTP procedures for front (lens) surface

DTP procedures for underside surface